product

ZXSTEELGROUP have more than 20 years experiences for sale steel rail and track accessories, including ASTM Standard rail, asce25, asce30, asce40, asce50, asce60, asce75, asce85 rail and rail clip, rail clamp, rail joint, rail rubber pad, etc. Can process according to your demand. Contact us for more details!

ASCE 40 rail, also known as 40 lb rail, is a standard type of rail that meets the specifications of the American Railway Engineering and Maintenance of Way Association (AREMA). It is mainly used in railway systems and industrial crane rails for medium speeds and loads.

| Q235B | Mechanical property | Chemical composition | |||||||||

| Yield strength | Tensile strength | Elongation | Hardness | C | Si | Mn | S | P | |||

| MPa ≥ | kg/mm² | MPa | kg/mm² | min | HB | ≤ | ≤ | ≤ | |||

| 235 | 24 | 375-460 | 38-47 | 26% | 0.12-0.22 | 0.3 | 0.30-0.70 | 0.045 | 0.045 | ||

| 55Q | Mechanical property | Chemical composition | |||||||||

| Yield strength | Tensile strength | Elongation | Hardness | C | Si | Mn | S | P | |||

| MPa ≥ | kg/mm² ≥ | MPa ≥ | kg/mm² ≥ | min | HB ≥ | ≤ | ≤ | ||||

| 685 | 69 | 26% | 197 | 0.5-0.6 | 0.15-0.35 | 0.60-0.90 | 0.04 | 0.04 | |||

| Product Name | American Standard Rail | ||||||

| Standard | ASTM A1/AREMA | ||||||

| Model | DIMENSION | Weight | Material | Length | |||

| Head Width(mm) | Rail Height(mm) | Bottom Width(mm) | Web Thickness(mm) | (KG/M) | (M/PC) | ||

| ASCE25 | 38.1 | 69.85 | 69.85 | 7.54 | 12.4 | 700 | 6-12 |

| ASCE30 | 42.86 | 79.38 | 79.38 | 8.33 | 14.88 | 700 | 6-12 |

| ASCE40 | 47.62 | 88.9 | 88.9 | 9.92 | 19.84 | 700 | 6-12 |

| ASCE50 | 54 | 98.4 | 98.4 | 11.11 | 24.855 | 700 | 6-12 |

| ASCE60 | 60.32 | 107.95 | 107.95 | 12.3 | 29.76 | 700 | 6-12 |

| ASCE75 | 62.71 | 122.24 | 122.74 | 13.49 | 37.2 | 900A/1100 | 12-25 |

| ASCE85 | 65.09 | 131.76 | 131.76 | 14.29 | 42.17 | 900A/1100 | 6-12 |

ASCE 40 rail is mainly made of 55Q carbon steel or U50Mn low alloy steel, which combines high strength and wear resistance; some high-end products are made of U71Mn material, which further improves fatigue resistance, and is suitable for frequent starting and stopping of industrial and mining scenes.

ZongXiang is equipped with comprehensive processing capablities. We can process ASCE 40 rail according to customers reuirements, incuding cutting themto specific lengths, drilling holes, quenching the rai heads, and adding spray – codes for traceability.

ASCE 40 rail is a type of light-duty rail in the railway rail category, suitable for scenarios with low axle loads, temporary use, or medium to low-speed transportation. It is widely applied in industrial track systems with small to medium loads.

The ASCE rail is mainly used in industrial bridge-type/gantry crane runways and track transportation systems.

ASCE rails, developed under the standards of the ASCE, are designed specifically for lighter industrial applications, including:

Medium Duty Railway Transport

ASCE 40 rail (unit weight 19.84 kg/m) as American Standard medium load rails are widely used in railway systems with medium speed and load:

Ordinary passenger and freight lines: For railway lines with a speed of ≤ 120 km/h, able to withstand the dynamic pressure and impact loads of train operation, especially suitable for freight trains transporting coal, ore and other bulk goods.

Specialised tracks for mining areas: In the internal transport routes of mining areas, ASCE 40, with its high compressive strength and abrasion resistance (made of materials such as 700 series carbon steel), can be adapted to the needs of high-frequency, medium-load operation of mine cars.

Yards and grouping stations: Sidings for railway grouping stations and vehicle sections, supporting the movement of locomotive shunting and maintenance equipment, compatible with standard gauges (1435 mm) and a variety of fastening systems (e.g., slatted fasteners).

Industrial and Harbour Crane Rails

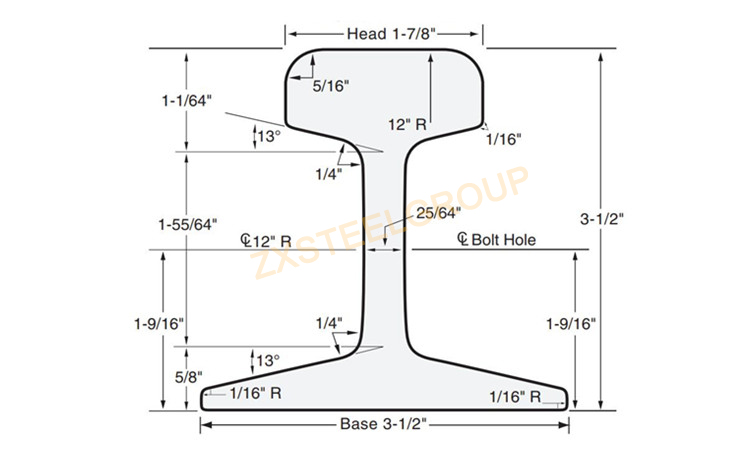

Port gantry cranes and container cranes: Its I-beam cross-section (rail head 47.62mm, rail height 88.9mm) is designed to spread the load, adapting to the load-bearing requirements of 20-50 tonnes for lifting systems. The high manganese steel material (e.g. U71Mn) further improves impact resistance and reduces rail deformation.

Automated warehousing logistics rail: Suitable for logistics equipment in the warehouse mobile rail, modular design to support rapid splicing, reduce installation and maintenance costs.

Heavy equipment rails in factories: Such as material transport rails or production line rails in steel mills, with rubber cushions to reduce vibration and noise and prolong service life.

Temporary Works and Special Scenarios

With its light weight (33% lighter than ASCE 60) and flexible deployment, ASCE 40 rail is suitable for the following scenarios:

Temporary tracks for construction sites: Supporting the movement of heavy machinery such as bridge erectors and shield machines, using quick-release fasteners and lightweight sleepers (e.g., anticorrosive wood sleepers or composite sleepers) to improve construction efficiency.

Mining equipment mobile line: Laying temporary transport track in open or underground mines, adapting to complex terrain and high-frequency vibration environment, reducing the risk of track fatigue fracture

Military and emergency engineering: As a wartime or post-disaster rapid laying track, support the rapid deployment of material transport equipment

Special Environments and International Projects

ASCE 40 rails are adapted to diverse environments through material optimisation and surface treatment:

Highly corrosive environments: ZongXiang offers galvanised surfaces or zinc-rich epoxy primers for coastal salt spray areas or humid climates, extending the rust protection cycle.

Cross-border railway projects: As a representative type of American Standard rail, it has been exported to the Americas and South East Asia for railway upgrading projects.