product

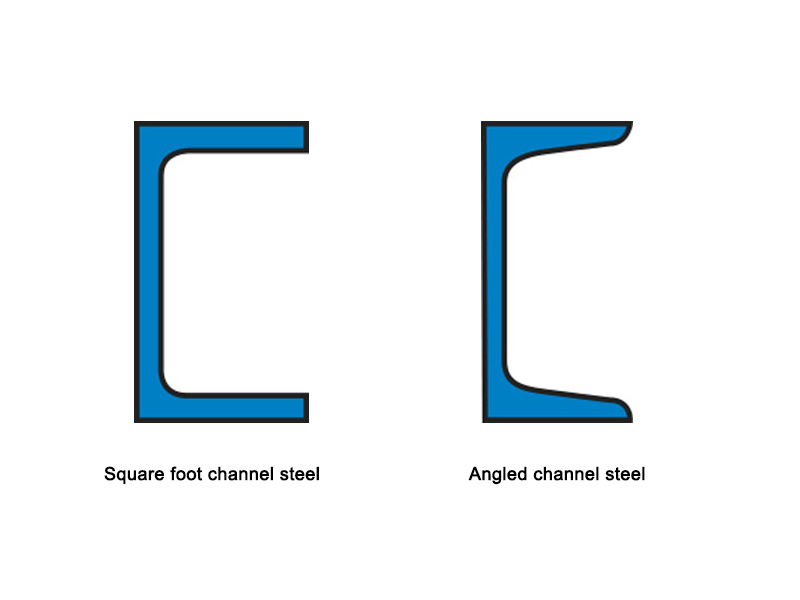

Channel steel is rolled from steel plate into oblique feet or square feet. Consists of a vertical back called a web and two horizontally extending flanges at the top and bottom, with filleted corners, ideal for all structural applications, general fabrication, fabrication and repair.

Channel steel is rolled from steel plate into oblique feet or square feet. Consists of a vertical back called a web and two horizontally extending flanges at the top and bottom, with filleted corners, ideal for all structural applications, general fabrication, fabrication and repair.

Compared with products such as I-beam, channel steel is lighter but weaker. Compared to angle iron or flat steel, channel steel provides more support without adding much weight. Channel steel can be welded to support or suspend various facilities, and is often used in combination with I-beams.

Because the bending axis of the channel is not centered on the flange width, the channel is not as strong as I-beams or wide-flange beams. In addition, square-footed channels allow for simpler connections than slanted-footed channels.

UPN is the European standard inclined foot channel steel, which is most suitable for applications that require a strong steel frame, such as warehouses. UPE is European standard square foot channel steel, with smaller thickness and wider square foot, relatively lighter weight and cost advantage, it is a good substitute for UPN series.

Hot-rolled and cold-rolled channel steel has a range of excellent qualities that make it the standard fixture for many commercial and industrial applications. Steel advantages for channels include:

Application of channel steel:

Tracks and sliders for machines, doorways, etc.

Building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing

Architectural frames and supports, industrial frames and supports

British Standard BS 4-1:1993

| SIZE | unit weight | high(h) | width(b) | waist thick(s) | thick legs(t) |

| kg/m | mm | mm | mm | mm | |

| 432 x 102 x 65 | 65.5 | 431.8 | 101.6 | 12.2 | 16.8 |

| 381 x 102 x 55 | 55 | 381 | 101.6 | 10.4 | 16.3 |

| 305 x 102 x 46 | 46.2 | 304.8 | 101.6 | 10.2 | 14.8 |

| 305 x 89 x 42 | 41.8 | 304.8 | 88.9 | 10.2 | 13.7 |

| 254 x 89 x 36 | 35.7 | 254 | 88.9 | 9.1 | 13.6 |

| 254 x 76 x 28 | 28.2 | 254 | 76.2 | 8.1 | 10.9 |

| 229 x 89 x 33 | 32.7 | 228.6 | 88.9 | 8.6 | 13.3 |

| 229 x 76 x 26 | 26.1 | 228.6 | 76.2 | 7.6 | 11.2 |

| 203 x 89 x 30 | 29.8 | 203.2 | 88.9 | 7.6 | 12.3 |

| 203 x 76 x 24 | 23.9 | 203.2 | 76.2 | 7.1 | 11.2 |

| 178 x 89 x 27 | 26.8 | 177.8 | 88.9 | 7.6 | 12.3 |

| 178 x 76 x 21 | 20.8 | 177.8 | 76.2 | 6.6 | 10.3 |

| 152 x 89 x 24 | 23.9 | 152.4 | 88.9 | 7.1 | 11.6 |

| 152 x 76 x 18 | 17.9 | 152.4 | 76.2 | 6.4 | 9 |

| 127 x 64 x 15 | 14.9 | 127 | 63.5 | 6.4 | 9.2 |

| 102 x 51 x 10 | 10.4 | 101.6 | 50.8 | 6.1 | 7.6 |

| 76 x 38 x 7 | 6.7 | 76.2 | 38.1 | 5.1 | 6.8 |

Standard of Chinese Mill Plant GB/T 707-1988

| SIZE | unit weight | high(h) | width(b) | waist thick(s) | thick legs(t) |

| kg/m | mm | mm | mm | mm | |

| 432 x 102 x 65 | 65.5 | 431.8 | 101.6 | 12.2 | 16.8 |

| 381 x 102 x 55 | 55 | 381 | 101.6 | 10.4 | 16.3 |

| 305 x 102 x 46 | 46.2 | 304.8 | 101.6 | 10.2 | 14.8 |

| 305 x 89 x 42 | 41.8 | 304.8 | 88.9 | 10.2 | 13.7 |

| 254 x 89 x 36 | 35.7 | 254 | 88.9 | 9.1 | 13.6 |

| 254 x 76 x 28 | 28.2 | 254 | 76.2 | 8.1 | 10.9 |

| 229 x 89 x 33 | 32.7 | 228.6 | 88.9 | 8.6 | 13.3 |

| 229 x 76 x 26 | 26.1 | 228.6 | 76.2 | 7.6 | 11.2 |

| 203 x 89 x 30 | 29.8 | 203.2 | 88.9 | 7.6 | 12.3 |

| 203 x 76 x 24 | 23.9 | 203.2 | 76.2 | 7.1 | 11.2 |

| 178 x 89 x 27 | 26.8 | 177.8 | 88.9 | 7.6 | 12.3 |

| 178 x 76 x 21 | 20.8 | 177.8 | 76.2 | 6.6 | 10.3 |

| 152 x 89 x 24 | 23.9 | 152.4 | 88.9 | 7.1 | 11.6 |

| 152 x 76 x 18 | 17.9 | 152.4 | 76.2 | 6.4 | 9 |

| 127 x 64 x 15 | 14.9 | 127 | 63.5 | 6.4 | 9.2 |

| 102 x 51 x 10 | 10.4 | 101.6 | 50.8 | 6.1 | 7.6 |

| 76 x 38 x 7 | 6.7 | 76.2 | 38.1 | 5.1 | 6.8 |

Grade: A36,Q235,Q345,S235JR,S355JR,S355,SS400,SM400A,SM400B,SS490,SM490,SS540

Surface treatment: Pickling, shot blasting, sand blasting, high pressure water, painting, galvanizing