product

ZXSTEELGROUP have more than 20 years experiences for sale steel rail and track accessories, including GB standard heavy rail, 38kg, 43kg, 50kg, 60kg, 75kg rail and rail clip, rail clamp, rail joint, rail rubber pad, etc. Can process according to your demand. Contact us for more details!

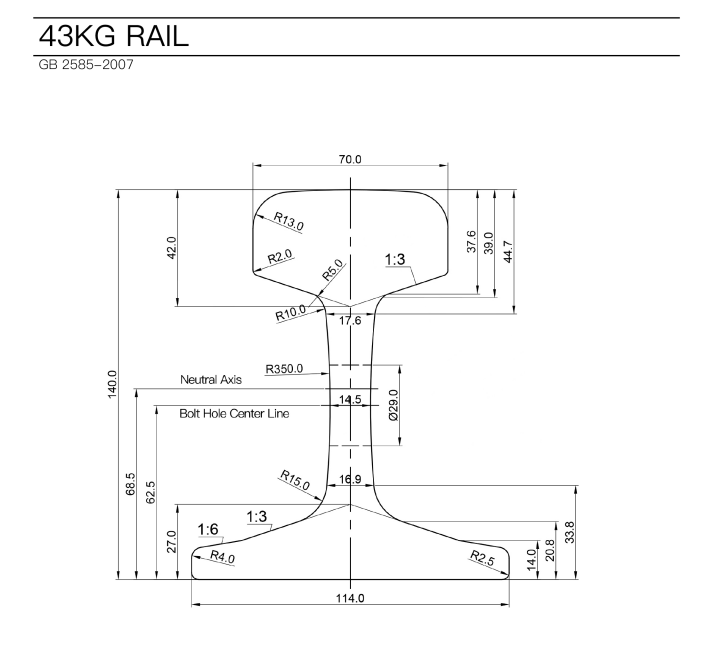

GB 43KG heavy rail, manufactured in strict compliance with Chinese National Standard GB/T 2585, offers a robust and economical solution for light to medium-duty railway tracks in various applications worldwide.

43kg heavy rail length are furnished from 12-25meter. Other lengths are available upon request from ZongXiang. Steel Grade are produced to various qualities and specifications as required by our clients.

| Product Name | CHINESE STANDARD HEAVY RAIL | ||||||

| Standard | GB/T2585-2007 | ||||||

| Model | DIMENSION | Weight | Material | Length | |||

| Head Width(mm) | Rail Height(mm) | Bottom Width(mm) | Web Thickness(mm) | (KG/M) | (M/PC) | ||

| GB 38KG | 68 | 134 | 114 | 13 | 38.733 | 50Mn/U71Mn | 12.5-25 |

| GB 43KG | 70 | 140 | 114 | 14.5 | 44.653 | 50Mn/U71Mn | 12.5-25 |

| GB 50KG | 70 | 152 | 132 | 15.5 | 51.514 | 50Mn/U71Mn | 12.5-25 |

| GB 60KG | 73 | 176 | 150 | 16.5 | 60.64 | 50Mn/U71Mn | 12.5-25 |

| GB 75KG | 70 | 192 | 150 | 20 | 74.4 | 50Mn/U71Mn | 12.5-25 |

| 50Mn | Mechanical property | Chemical composition | ||||||||||||

| Yield strength | Tensile strength | Elongation | Hardness | C | Si | Mn | S | P | Cr | Ni | Cu | |||

| MPa | kg/mm² | MPa | kg/mm² | min | HBW | ≤ | ≤ | ≤ | ≤ | ≤ | ||||

| ≥390 | ≥40 | ≥645 | ≥66 | 13% | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | 0.04 | 0.04 | 0.25 | 0.25 | 0.25 | ||

| U71Mn | Mechanical property | Chemical composition | ||||||||||||

| Yield strength | Tensile strength | Elongation | Hardness | C | Si | Mn | S | P | Cr | Ni | Cu | |||

| MPa | kg/mm² | MPa | kg/mm² | min | HBW | ≤ | ≤ | ≤ | ≤ | ≤ | ||||

| ≥390 | ≥40 | ≥880 | 9% | 0.65-0.76 | 0.15-0.35 | 1.1-1.4 | 0.03 | 0.03 | 0.25 | 0.25 | 0.25 | |||

Internationally Recognized Standard: P43 is a widely recognized rail specification with a long application history, especially in regions such as Asia, Africa, and the Middle East.

Balanced Strength and Durability: It achieves an excellent balance between load-bearing capacity (suitable for axle loads of approximately 18-22 tons) and cost efficiency.

Reliable Material with Superior Wear Resistance: High-strength steels such as 55Q and U71Mn are commonly used, which extend the service life and reduce maintenance costs.

Excellent Geometric Precision: Advanced rolling and straightening processes ensure smooth track laying, minimizing maintenance requirements.

Good Welding Performance: Standard materials (e.g., U71Mn) are easy to perform on-site flash welding or thermite welding.

Strict Quality Control: Strict chemical composition analysis, mechanical property testing, Ultrasonic Testing (UT), and appearance inspection are implemented throughout the production process.

To meet the diverse requirements of rail installation, underground transport, and industrial logistics, ZongXiang offer a full range of processing and customization services for GB2585-2007 standard heavy steel rails, covering models from 43kg to 75kg.

Custom Bending: Curved rails for crane tracks, mining systems, or circular applications. ZongXiang support hot and cold bending based on profile and radius needs.

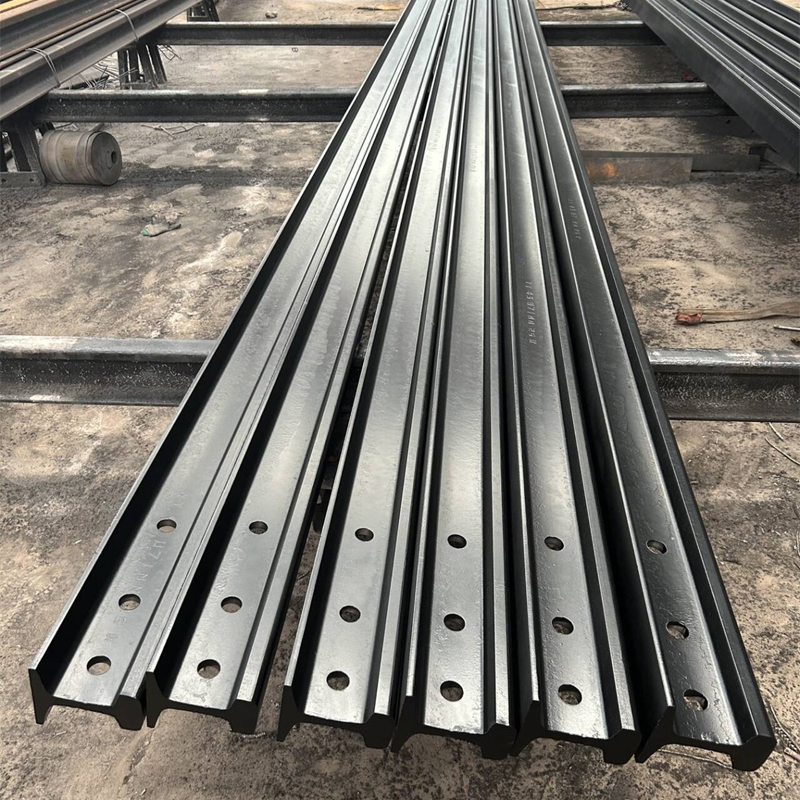

Precision Drilling: End or center drilling can be performed based on customer drawings or standard templates, allowing for the installation of fishplates or bolts.

Angle Cutting/Beveling: Rails can be cut to specific angles for tight-fitting joints or welding preparation. Clean edges with minimal deformation.

End Milling or Grinding: Flat milling or grinding of rail ends is available for applications requiring high alignment precision, such as long rail welding.

Surface Treatment (Sandblasting & Anti-Rust Oiling): Sandblasting: Removes scale and rust to improve surface adhesion; Oiling: Anti-rust oil coating protects the rails during long-distance or marine transportation.

Rail Bending: Curved rails can be custom-bent to a specified radius for use in turning sections, such as metro systems or mining railways. Detailed drawings or parameters from the customer are required.

Rail Welding: Long rail welding services are available, mainly for large-scale railway construction projects.

Industrial and Mining Railways

43kg rails are widely used in internal transportation lines of enterprises such as coal mines, non-ferrous metal mines, metallurgical plants, and chemical factories. They can not only adapt to the operation of heavy-duty trains with frequent operations but also be used for curves with smaller radii, featuring excellent track compatibility.

Crane Rail System

Suitable for the running tracks of overhead cranes and gantry cranes, commonly found in large workshops, mechanical processing workshops, logistics warehouses, etc. Due to its stable load-bearing capacity, 43kg rails can effectively support the repeated movement of cranes and reduce track deformation.

Temporary Construction Tracks

In municipal engineering, subway construction, tunnel excavation and other projects, they are used as temporary tracks for material transportation and equipment movement. With moderate weight and convenient laying, they can effectively improve construction efficiency and reduce costs.

Warehouse & Logistic Systems

It can serve as the basic track for automated storage systems and slide rail systems, used as the guiding path for mobile trolleys and small freight equipment. Combined with the installation of under-rail pads and rail clamps, it can achieve track stability in high-frequency operation scenarios.

Light-Duty or Branch Rail Lines

In some areas such as mountain railways, agricultural railways, and low-speed branch lines, 43kg rails, as a medium-sized rail solution, meet the functions of daily transportation and personnel passage.

As a professional supplier of mining rail, ZongXiang not only provides high-quality light steel rails but also a full range of compatible installation accessories, ensuring safe and efficient operation of the entire rail system. All accessories undergo strict quality control to perfectly match rails, enabling “one-stop procurement + worry-free installation.”

Fish Plates(Rail Joint Bar): Fish plates serve to connect steel rails and distribute loads, ensuring track stability. ZongXiang supplies fish plates for P43 rails, made of Q235B or 55Q. Common rail fishplate configurations with 6-hole, with standard lengths of 600mm, thickness of 22/24mm. Materials commonly used include ductile cast iron, Q235 rolled steel, and forged steel.

Bolts & Nuts: Fishplate bolts and nuts are essential for fastening fishplates to rails. ZongXiang provides fishplate bolts with diameters of 13-14mm, made from 8.8-grade or Q235, fully compliant with 43kg rails.

Rail Clips: Rail clamps are mainly used to firmly fix rails on the foundation or base plate, effectively preventing lateral displacement or loosening of the track during operation. ZongXiang can provide models such as the WJK series, KPO series, and DJ series, which are suitable for different installation environments and adapt to different rail base structures and compression methods.

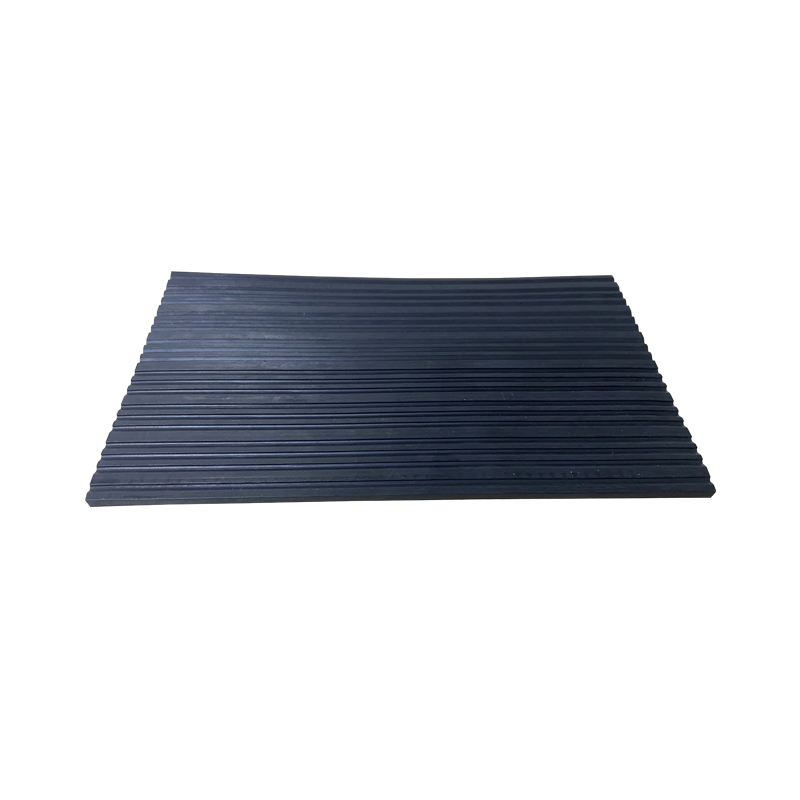

Rubber Pads: Rubber baseplates are used beneath the rails to absorb vibration and shock, helping reduce noise and extend track life. ZongXiang offer rubber matting for 9kg light rail bottoms, with a regular thickness of 510mm, made of highly elastic black natural rubber material, which can be customised to the size of the rail bottom.

Rail Soleplates: The base plate, also known as the sole plate, is an optional but important accessory used beneath the rail to provide enhanced stability and load distribution. They are especially useful when the rail is installed on concrete floors or steel beams, helping to reduce vibration, protect the substructure, and extend the life of both the rail and the foundation. Custom drilling and surface treatments are available to meet specific installation requirements. When combined with rail clips or anchor bolts, base plates offer a complete and reliable track fastening solution.

Alumothermic Welding kits for Rails: ZongXiang offers a full set of alumothermic welding equipment for crane rail track installation. Our solution uses an aluminum – iron oxide exothermic reaction to form high – strength, fatigue – resistant joints. With no need for complex power setups, it enables rapid on – site installation, making it a preferred choice for heavy – duty crane rails.