product

ZXSTEELGROUP have more than 20 years experiences for sale steel rail and track accessories, including GB standard crane rail, qu70, qu80, qu100, qu120 rail and rail clip, rail clamp, rail joint, rail rubber pad, etc. Can process according to your demand. Contact us for more details!

QU120 is a specific size of the Chinese standard QU crane rail series. The number “120” refers to the head width of the crane rail. Therefore, the QU120 rail head is 120 mm wide. QU120 rail is a high-strength specialized track solution widely used in industrial scenarios requiring heavy lifting and transportation, such as ports, shipyards, steel plants, and construction sites.

QU120 rail length are furnished from 6-12meter. Other lengths are available upon request from ZongXiang. Steel Grade are produced to various qualities and specifications as required by our clients.

| Product Name | China Standard Crane Rail | ||||||

| Standard | Crane Rail YB/T5055-2014 | ||||||

| Model | DIMENSION | Weight | Material | Length | |||

| Head Width(mm) | Rail Height(mm) | Bottom Width(mm) | Web Thickness(mm) | (KG/M) | (M/PC) | ||

| QU 70 | 70 | 120 | 120 | 28 | 52.8 | U71Mn | 12 |

| QU 80 | 80 | 130 | 130 | 32 | 63.69 | U71Mn | 12 |

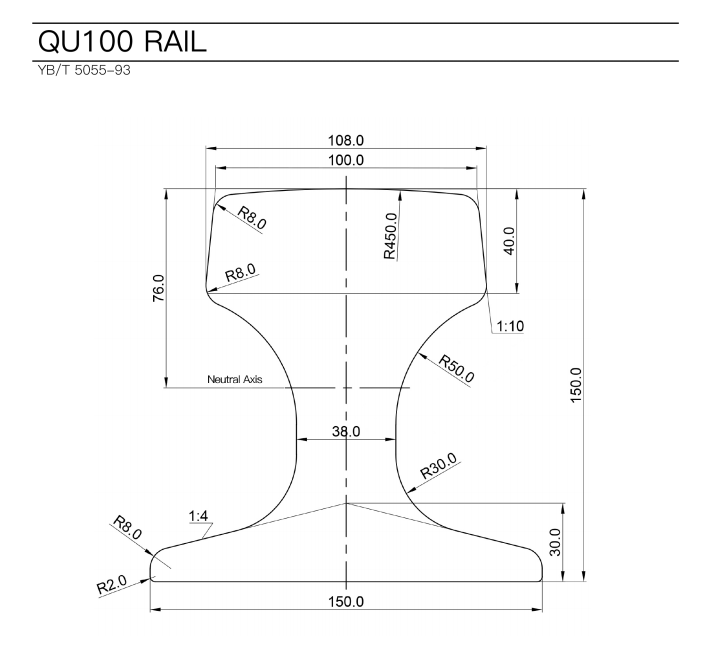

| QU 100 | 100 | 150 | 150 | 38 | 88.96 | U71Mn | 12 |

| QU 120 | 120 | 170 | 170 | 44 | 118.1 | U71Mn | 12 |

| U71Mn | Mechanical property | Chemical composition | ||||||||||||

| Yield strength | Tensile strength | Elongation | Hardness | C | Si | Mn | S | P | Cr | Ni | Cu | |||

| MPa | kg/mm² | MPa | kg/mm² | min | HBW | ≤ | ≤ | ≤ | ≤ | ≤ | ||||

| ≥390 | ≥40 | ≥880 | 9% | 0.65-0.76 | 0.15-0.35 | 1.1-1.4 | 0.03 | 0.03 | 0.25 | 0.25 | 0.25 | |||

QU120 crane rail is a high-strength specialized track solution widely used in industrial scenarios requiring heavy lifting and transportation, such as ports, shipyards, steel plants, and construction sites.

As a critical component in material handling infrastructure, it delivers unmatched performance across ports, shipyards, steel mills, and construction sites requiring heavy-load capacities and continuous operational reliability.

High-strength performance: QU120 rail, made of U71Mn alloy steel (tensile strength ≥900MPa, HB 280–320), resists deformation under heavy loads, ideal for cranes and railways. Maintains stability in high-frequency operations.

Durability: QU120 crane tracks are manufacturing using advanced rolling processes ensure excellent wear/corrosion resistance, performing reliably in harsh environments (salt, dust, extreme temps). Reduces maintenance by 30%.

Long service life: The optimized crystal structure provides excellent fatigue resistance, minimizing the risk of cracks and deformation and extending the rail service life by over 30%. Operators can reduce replacement frequency and maintenance costs, enhancing the operational efficiency of overall logistics or railway systems.

Safety-Oriented Design: The hardened rail head (HB 280-320 hardness) and high-precision geometry (straightness ≤1.5mm/m) ensure stable contact between wheels and rails, effectively preventing operational failures caused by wear or misalignment. This provides a safe and smooth running track for lifting equipment and trains.

As a leading crane rail supplier, ZongXiang offers meticulously engineered gantry crane rail and overhead crane rail solutions. We specialize in providing customizable gauge configurations ranging from 600mm to 1520mm, along with tailored cross – sectional parameters to meet diverse project requirements.

The standardized cross-sectional design (120mm rail head width, 170mm rail height) is compatible with international mainstream crane and railway wheel systems, supporting various equipment models such as European and American types. It can be flexibly applied to overhead cranes, gantry cranes, and small-to-medium railway branches.

As a professional supplier of QU model crane rails, ZongXiang not only provides high-quality QU120 rails but also a full range of compatible installation accessories, ensuring safe and efficient operation of the entire rail system. All accessories undergo strict quality control to perfectly match QU crane rails, enabling “one-stop procurement + worry-free installation.”

Fish Plates: Made of Q235B steel with hot-dip galvanizing, they connect QU-series rails with ±0.3mm precision for gap-free bolted joints and stable load transfer.

Rail Clamps: Designed for QU-model rail base, forged from 45# steel with dual anti-corrosive coating. Available in welded/bolted types, their elastic pads reduce vibrations between rails and foundations.

High-Strength Bolts: 8.8/10.9-grade sets meet ISO/GB standards, with Dacromet coating for 500+ hours of salt spray resistance—3x more durable than ordinary bolts.

Rubber Pads: Laid under QU-series rails, these natural/nitrile rubber pads (60-70HA hardness) come in 5/8/10mm thicknesses to buffer pressure and reduce noise.

Rail Pressure Plates: Crafted from QT400-18 ductile iron (galvanized, 400MPa+ strength), their curved design fits QU model rail bases perfectly, minimizing stress for heavy-duty applications.

Alumothermic Welding kits for Rails: ZongXiang offers a full set of alumothermic welding equipment for crane rail track installation. Our solution uses an aluminum – iron oxide exothermic reaction to form high – strength, fatigue – resistant joints. With no need for complex power setups, it enables rapid on – site installation, making it a preferred choice for heavy – duty crane rails.