product

ZXSTEELGROUP have more than 20 years experiences for sale steel rail and track accessories, including DIN standard crane rail, a45, a55, a65, a75, a100, a120, a150 rail and rail clip, rail clamp, rail joint, rail rubber pad, etc. Can process according to your demand. Contact us for more details!

ZongXiang supplies DIN 536-compliant A55 rail manufactured from 71Mn steel, delivering a tensile strength of ≥450MPa. Engineered for critical rail infrastructure applications, including: railway systems, metro networks, light rail transit etc.

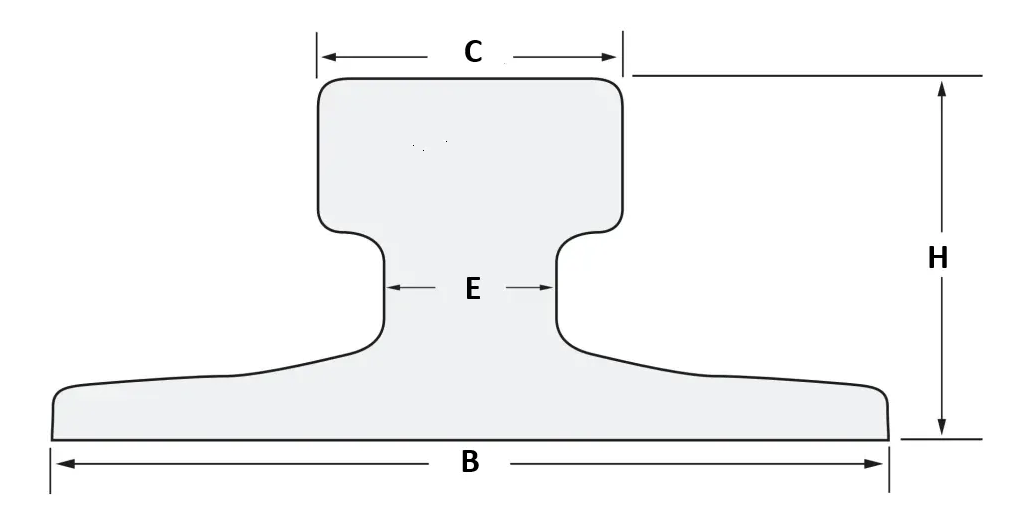

| Profile | Standard | H(mm) | B(mm) | C(mm) | E(mm) | Weight(kg/m) |

| A55 | Din536 | 65 | 150 | 55 | 31 | 31.8 |

Compliant with DIN standards: The A55 rail is manufactured strictly in accordance with DIN 536 , ensuring dimensional accuracy and compatibility with global crane rail systems. This minimizes on-site adjustments, enhancing installation efficiency and operational safety.

Optimal Balance of Strength and Weight: The A55 rail has a theoretical weight of 31.8 kg/m, balancing load-bearing capacity with material efficiency. It is suitable for medium-load bridge and gantry crane systems.

Material diversity to meet diverse application requirements: We offer materials including 50Mn, 900A, and U71Mn tailored to your operating conditions. Surface hardening or anti-corrosion treatments can be added per customer specifications to extend service life and reduce maintenance costs.

Precision Manufacturing and Rigorous Quality Inspection: ZongXiang employs strict factory tolerances and quality inspection procedures to ensure rail geometric accuracy and surface quality, thereby reducing wheel-rail wear and enhancing equipment operational reliability and service life.

Customized Services Tailored to Project Requirements: We offer rail beveling, custom lengths, drilling, machining, and surface treatment services based on client drawings. This reduces on-site fabrication and accelerates installation progress.

20+ Years Export Experience: With 20+ years of export experience, ZongXiang offers full export documentation, third-party inspection (SGS/BV), and reliable packaging for overseas shipment.

One-to-one project support: We offer one-on-one project support, including rail selection guidance, drawing confirmation, and accessory matching. Technical team with deep industry expertise ensures smooth implementation for international projects