product

ZXSTEELGROUP have more than 20 years experiences for sale steel rail and track accessories, including DIN standard crane rail, a45, a55, a65, a75, a100, a120, a150 rail and rail clip, rail clamp, rail joint, rail rubber pad, etc. Can process according to your demand. Contact us for more details!

The DIN 536 A75 rail, also known as A75 crane rail or A75 steel rail, is a heavy-duty rail designed in accordance with the European DIN 536 standard. With excellent load-bearing capacity, superior wear resistance, and high impact toughness, the A75 rail is widely used in port cranes, steel plants, mining transportation, and heavy-duty rail systems.

If you are looking for reliable A75 crane rail dimensions, a75 rail weight per meter, or detailed a75 rail material specifications, ZongXiang can provide precise technical support, guaranteed quality, and flexible supply solutions.

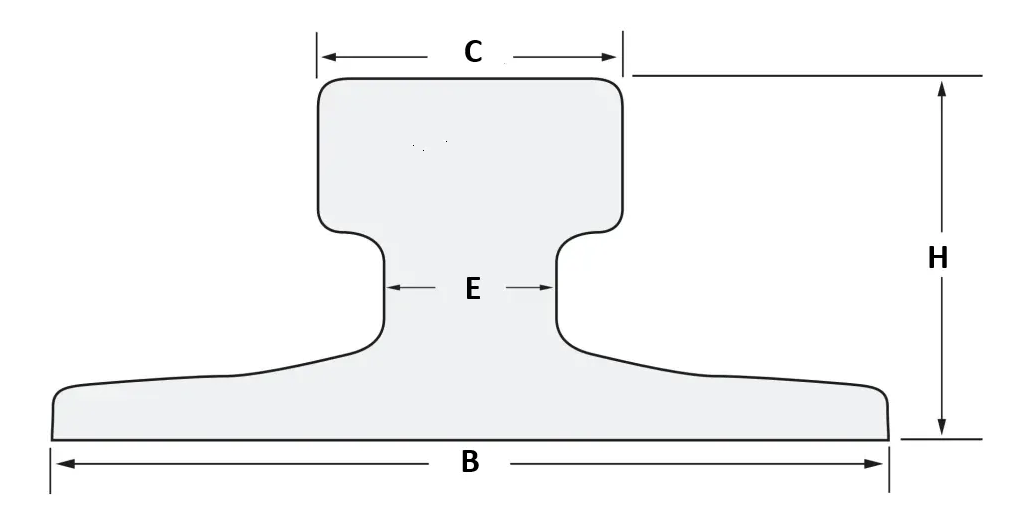

| Profile | Standard | H(mm) | B(mm) | C(mm) | E(mm) | Weight(kg/m) |

| A75 | Din536 | 85 | 200 | 75 | 45 | 56.2 |

DIN 536 Standard A75 rail length are furnished from 6-12meter. Other lengths are available upon request. Steel Grade are produced to various qualities and specifications as required by our clients.

DIN 536 A75 rail is a heavy duty crane rail conforming to the German Industrial Standard (DIN 536).

A75 rail is made of high quality U71Mn steel or 900A grade steel with high strength and abrasion resistance, suitable for dynamic loads and frequent start-stop scenarios.

High Load-Bearing Capacity: High load capacity: Designed for heavy-duty crane systems and industrial tracks

Superior wear resistance: Longer service life and reduced maintenance costs

Standardized production: Fully compliant with DIN 536 A75 rail standard, ensuring compatibility and interchangeability

Global supply capability: Exported to Europe, Southeast Asia, Middle East, and Africa with proven track record

Customization available: We provide cutting, drilling, and heat-treatment processing services for your project needs

20+ Years Export Experience: With 20+ years of export experience, ZongXiang offers full export documentation, third-party inspection (SGS/BV), and reliable packaging for overseas shipment.

One-to-one project support: We offer one-on-one project support, including rail selection guidance, drawing confirmation, and accessory matching. Technical team with deep industry expertise ensures smooth implementation for international projects