Flat bars and square bars are two commonly used metal profiles in construction, manufacturing, and fabrication industries. While they may seem similar at a glance—both being long, solid metal bars—they differ significantly in shape, usage, mechanical properties, and applications. Understanding the differences between a flat bar and a square bar is important when selecting materials for specific structural or industrial needs.

1. Shape and Dimensions

The primary difference lies in their cross-sectional shape:

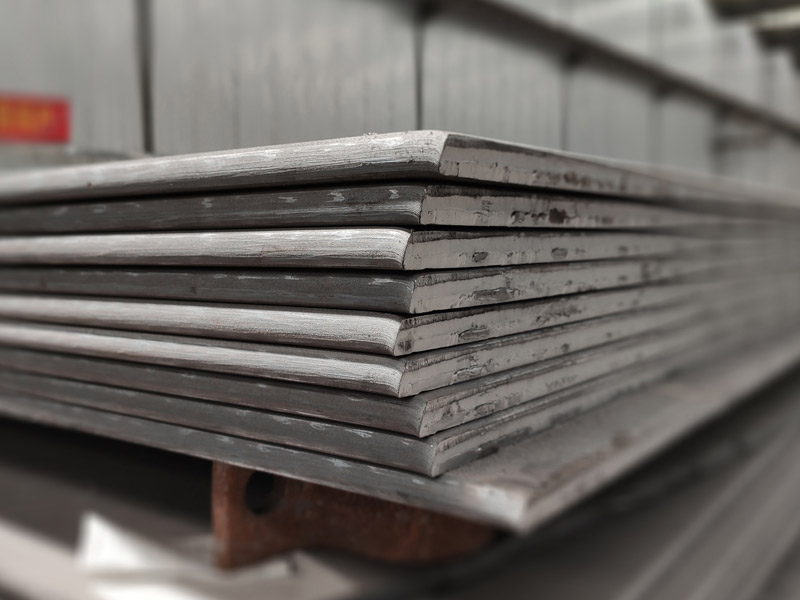

Flat Bar: A flat bar has a rectangular cross-section. Its width is significantly greater than its thickness, resembling a flat strip.

Square Bar: A square bar has a square cross-section with all four sides of equal length.

This difference in shape affects how each bar behaves under stress and where it can be best utilized.

2. Strength and Load Distribution

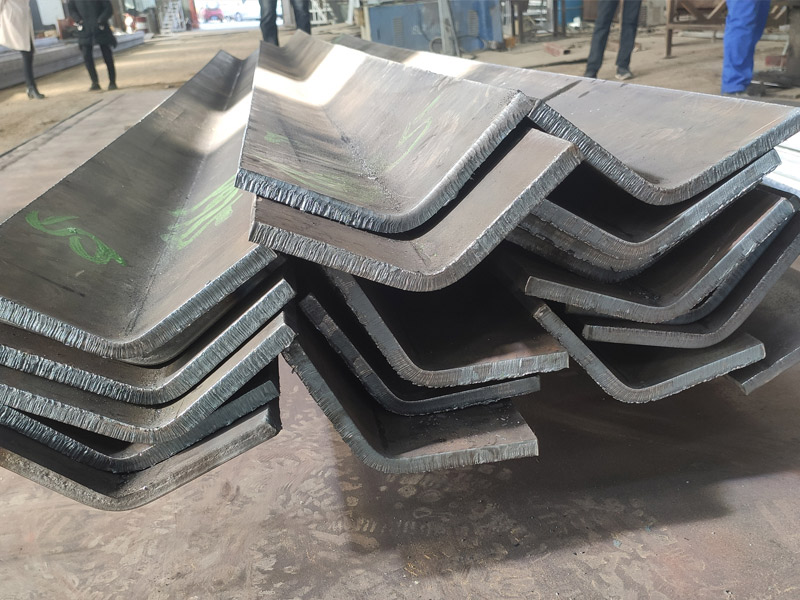

Because of its equal sides, a square bar has uniform strength in all directions of the cross-section. This makes it particularly useful for applications where multidirectional stress or torsion is involved. Square bars are often used in construction where high strength and even load-bearing capabilities are necessary.

In contrast, flat bars are stronger in the direction of their thickness and weaker in the width direction. While they can bear significant tensile and compressive loads, they are more prone to bending across the wider face. This makes them suitable for applications where directional force is controlled or predictable, such as support brackets or frames.

3. Weight and Cost Considerations

Because of their geometry, square bars typically contain more material per meter than flat bars (for comparable width/thickness), making them heavier. This can affect transportation costs, handling, and overall project weight. Flat bars, being lighter, are often a more economical choice when high structural integrity is not required.

Additionally, square bars may be more expensive due to the increased volume of material used and the more complex rolling process during manufacturing.

4. Fabrication and Machining

Flat bars are often easier to cut, drill, weld, and bend due to their thinner cross-section. They are highly versatile and can be modified for a variety of uses, including furniture framing, signage, fencing, and architectural components.

Square bars, being thicker and more uniform, may require more effort and specialized tools to machine. However, their shape makes them ideal for precision machining applications, tool manufacturing, and shafts or axles where uniform geometry is important.

5. Common Applications

Flat Bar Applications:

Structural support in buildings

Brackets, frames, and reinforcements

Base plates and braces

Fabricated metal components

Square Bar Applications:

Tool and die making

Machine parts like axles and spindles

Ornamental ironwork

Heavy-duty structural components

Conclusion

While flat bars and square bars may appear similar in function as metal stock, their different shapes result in distinct mechanical and structural characteristics. Flat bars are best suited for lightweight, versatile applications where directional strength is sufficient, while square bars are preferred for high-strength and precision-based projects. Choosing the right bar depends on the specific requirements of strength, weight, cost, and fabrication complexity in a given project.